The EcoSec project

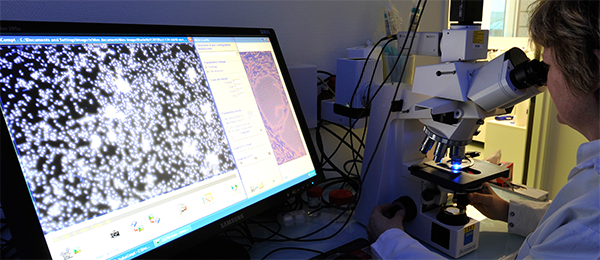

The EcoSec project aims at reducing the environmental impact of hygiene procedures in refrigerated food processing plants through optimal use of air drying.

Context

Cleaning and disinfection (C&D) are among the most important hazard control measures in refrigerated ready-to-eat food processing plants. However, these procedures require large amounts of water and generate huge volumes of sewage with high loads of cleaning agents and disinfectants. Additionally, some of those products may cause occupational dermatitis. More sustainable C&D strategies are therefore needed. Several food business operators have already noted the positive effects of adding an air-drying step after C&D to dry surfaces and thus kill part of bacteria that are not detached from surfaces and control their growth. However, air drying is applied empirically and no attempts have been made to define optimal air drying conditions.

Listeria monocytogenes is the most threatening pathogenic bacterium in refrigerated food processing plants since listeriosis has a high lethality rate ranging from 20 to 30%. The bacterium is able to persist even though correct cleaning and disinfection are applied. Moreover, L. monocytogenes has a low susceptibility to desiccation. This species has therefore been chosen to look for the best air drying strategies, to study the mechanisms involved in bacterial responses to hydric stress and for a better understanding of bacterial persistence in food industry premises.

Listeria monocytogenes is the most threatening pathogenic bacterium in refrigerated food processing plants since listeriosis has a high lethality rate ranging from 20 to 30%. The bacterium is able to persist even though correct cleaning and disinfection are applied. Moreover, L. monocytogenes has a low susceptibility to desiccation. This species has therefore been chosen to look for the best air drying strategies, to study the mechanisms involved in bacterial responses to hydric stress and for a better understanding of bacterial persistence in food industry premises.

Airflow and climatic conditions at all surfaces in a refrigerated food processing room have an impact on drying and thus on survival of bacteria which are not eliminated by C&D. Those phenomena will thus be studied at the large scale of a processing room. Furthermore, energy consumption to control air humidity, notably by the most commonly used mechanical cold technique, ranges from one-third to two-thirds of the energy needed for air handling. For this reason, less energy-consuming techniques including those using desiccation solutions will be investigated during the project.

Airflow and climatic conditions at all surfaces in a refrigerated food processing room have an impact on drying and thus on survival of bacteria which are not eliminated by C&D. Those phenomena will thus be studied at the large scale of a processing room. Furthermore, energy consumption to control air humidity, notably by the most commonly used mechanical cold technique, ranges from one-third to two-thirds of the energy needed for air handling. For this reason, less energy-consuming techniques including those using desiccation solutions will be investigated during the project.

Objectives

Operational objectives

-

To define optimal air drying conditions in terms of

- lethal impact on L. monocytogenes,

- distribution of relative humidity, temperature and air velocity in a food processing room

- sustainability of various air-drying techniques

-

The project will assess whether optimal air-drying conditions can promote

- the use of environmentally friendly C&D products,

- a decreased disinfection frequency, and thus decreased sewage volume and biocide release into the environment,

without affecting, and even improving, food safety and occupational health.

Scientific objectives

- To assess the impact of exposure to drying conditions on death, resistance, adaptation in Listeria monocytogenes.

- To describe and comprehend the corresponding cellular (plasma membrane) and molecular mechanisms at transcriptomic, lipidomic and proteomic levels

- To identify viability markers so as to develop an assay to detect cells that are not detectable by culture.

- To investigate the impact of desiccation on the persistence potential of L. monocytogenes using experimental and mathematical modeling studies. Those studies will take into account the multiple conditions under which the bacterium can be found (associated microflora, type of food soil, surface texture of materials, type of C&D products etc.)

- To develop a numerical method for characterizing hot spots / moist areas with low / high air velocity in a large volume for transfer to industrial food processing rooms thereby providing a practical optimization tool for food business operators

- To compare air drying techniques in terms of energy consumption and flexibility needed to propose sustainable techniques adapted to food safety objectives.

Partners

|

Anses - Laboratoire de sécurité des aliments (Maisons-Alfort) | Brigitte Carpentier |

|

Unité de Procédés alimentaires et microbiologiques, Dijon (PAM) | Laurent Beney |

|

Institut national de la recherche agronomique, Theix (INRA) | Michel Hébraud |

|

Institut national de recherche en sciences et technologies de l'environnement et l'agriculture, Antony | Onrawee Laguerre |

|

Maison du Froid Conseil, St Parres aux Tertres (MF Conseil) | Jacques Guilpart |

|

DESSICA, Trévoux | Adam Tchaïkowski |

|

Groupe Labeyrie Fine Foods, Came | Yves Gasnier |